The Politec method

At Politec, collaboration with the customer is fundamental: the final production is the result of a tried-and-tested procedure made up of specific intermediate steps aimed at rendering the product tailor-made for its intended use.

Expert advice and identification

of the specific requirement

Each project is a case in itself and the requirements can be complex: Before commencing production, Politec submits possible strategies to the customer and verifies the ideal solutions or handling the intervention.

Each proposal starts from an examination of the physical-chemical stresses to which the product is subjected. In each case, and at the customer’s request, Politec can also carry out an inspection directly at the company’s premises.

Design

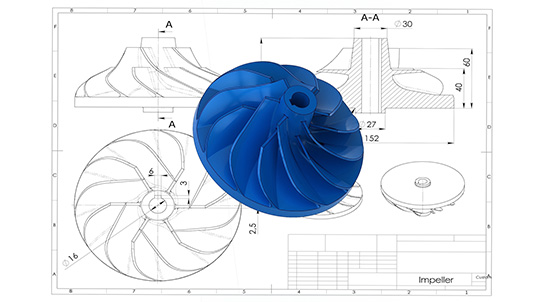

Once the conditions of use have been ascertained (such as, for example, the chemical environment and the operating temperature), the design of the hot-casting polyurethane product is done starting from a drawing or by carrying out a reverse-engineering operation on a sample.

The best materials are then chosen for the production of the items to be manufactured, and the moulds are subsequently designed.

Production

The production phase involves the pouring of the raw materials into the moulds and subsequent polymerisation in the oven. The raw components are preheated and properly mixed in the right proportions, either using a manual system or by means of a dedicated automatic machine.

After being left in the oven for about twenty hours, the items produced are removed from the mould and are then ready for the finishing and checking phase. At the beginning and at the end of production, the machine is calibrated to guarantee the expected physical-chemical characteristics.

Quality control and verification

The final step before delivery begins with verifying the absence of bubbles on the surface or the presence of defects that can be caused by anomalies in the chemical reaction between the raw materials used in the production process.

Politec subsequently verifies the dimensions of the product, and finally the hardness of the hot and cold product to check for any discrepancies in the stoichiometry of the chemical reagents.